NEWS

Contents

Eccentricity detection stabilizer development

Background of the Development

Since launching the DS Audio brand in October 2013, we have had the pleasure of connecting with audio enthusiasts around the world over the past nine years. Many of our customers invest hundreds of thousands of yen—sometimes even tens of millions of yen—in their turntables.

However, despite such large investments in high-end equipment, almost no one pays attention to a major factor that can degrade system performance: record eccentricity, which significantly worsens wow and flutter (speed fluctuation). Neither users nor the media have given much attention to this issue. That strong sense of contradiction was the initial trigger that led us to develop the ES-001 eccentricity detection stabilizer.

Let me now explain briefly, from a technical perspective, why we focused on this issue.

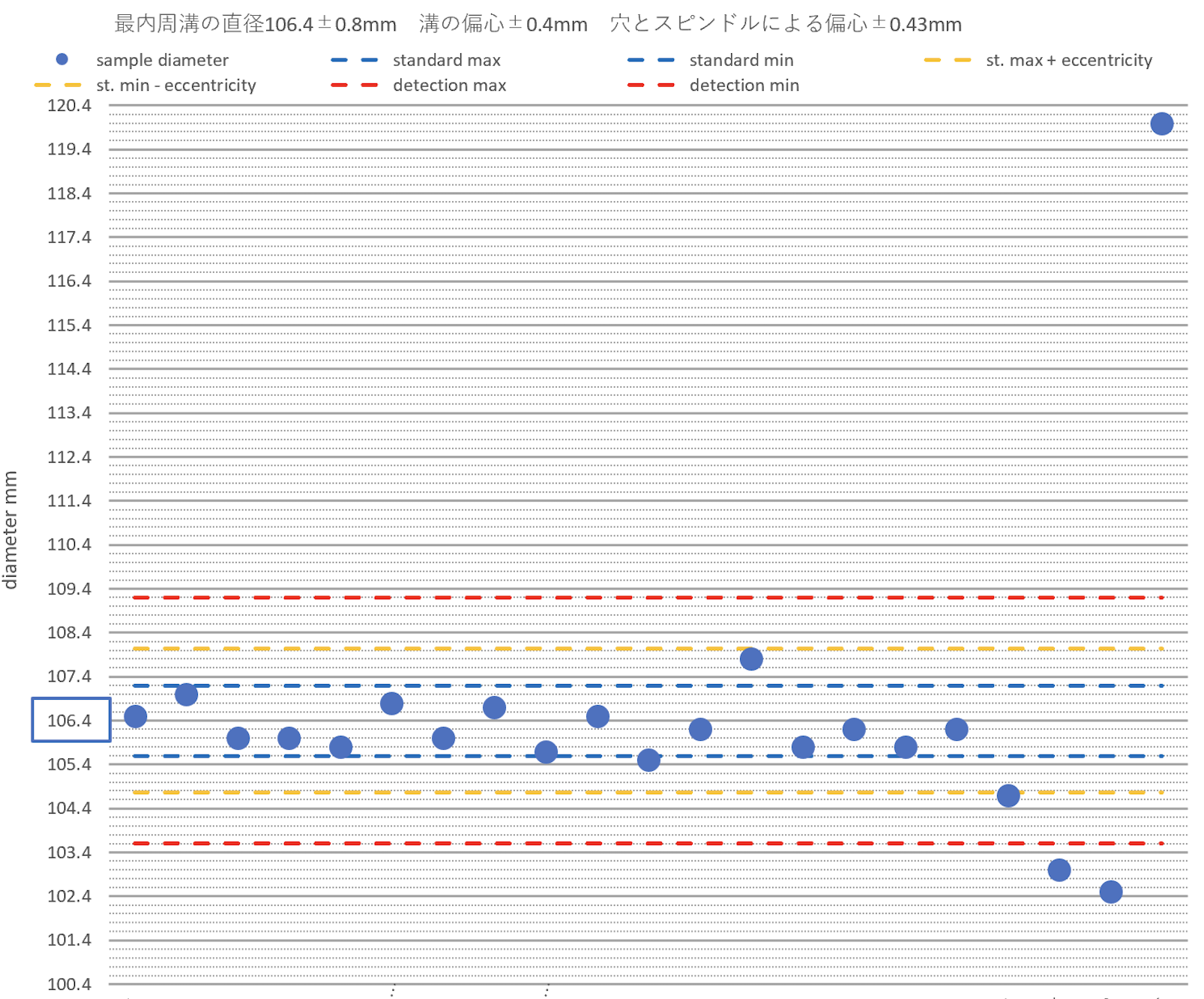

According to standards, the center hole diameter of a vinyl record is 7.24 mm with a tolerance of +0.09 mm / -0 mm, and the turntable spindle diameter is specified to be between 7.05 mm and 7.15 mm. In the worst-case scenario—when the spindle is at the minimum and the record hole at the maximum—there can be a gap of 0.28 mm. This results in a possible eccentricity (offset from the center) of 0.14 mm.

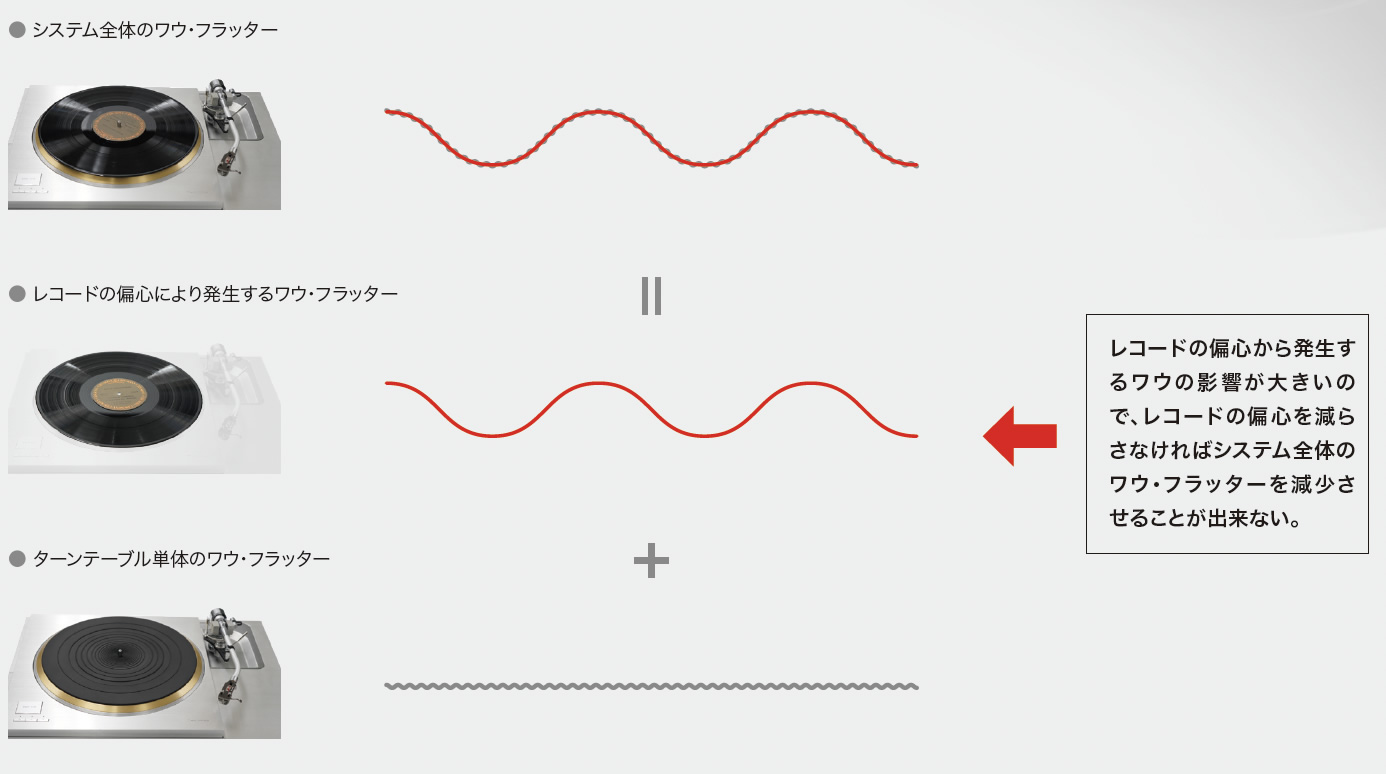

Moreover, there is a standard that limits the offset between the center hole and the groove spiral to 0.2 mm. When both conditions are at their worst, the combined eccentricity can be as large as 0.34 mm. Even if the turntable itself has zero wow and flutter, this level of eccentricity at the innermost groove of the record can result in a wow of about 0.15% (WTD RMS).

To put that into perspective, high-end turntables typically have wow and flutter values of around 0.008%. This means the wow caused by record eccentricity can be more than 20 times greater.

What this tells us is that wow caused by eccentricity often far exceeds the wow and flutter from the turntable itself. As a result, even if you purchase a highly accurate and expensive turntable, you may not be able to enjoy its true performance unless you eliminate record eccentricity.

To achieve accurate and faithful analog playback, we concluded that minimizing record eccentricity is essential. That’s why we decided to start the development of this eccentricity detection stabilizer.

What Problems Arise from High Wow and Flutter?

When wow and flutter (speed fluctuation) values are high, meaning the rotation is unstable, two major issues occur:

-

The playback speed becomes unstable, so the sound is not reproduced at the correct frequency. For example, even if a 3 kHz tone is recorded on a record, if the wow and flutter are large, it will not be reproduced as a 3 kHz tone. This is a serious issue for any playback system aiming to faithfully reproduce the original recording.

-

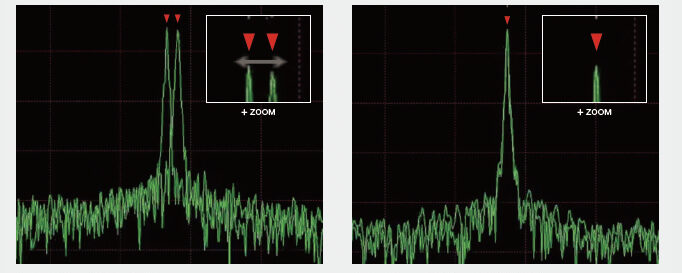

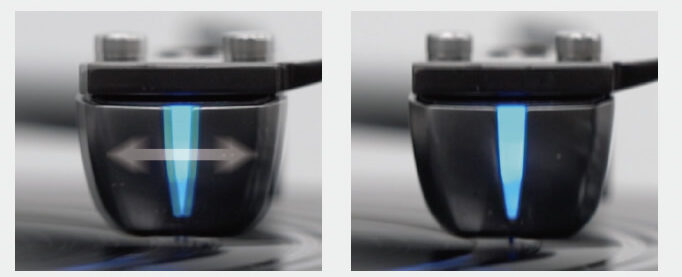

When a record is off-center and the tonearm traces it, the cartridge is forced to sway side to side. This causes it to trace the groove from a position significantly displaced from its optimal operating point. As a result, phase differences between the left and right channels occur, which can be heard as a blurred sound or unstable stereo image.

Through careful listening tests, we began to understand just how strongly this mechanical side-to-side movement affects the sound. This is because the cartridge is designed to read groove modulations on the order of a few microns, but with eccentricity, it is forced to swing by hundreds of microns side to side. Once eccentricity is eliminated and this lateral motion is reduced, the cartridge can trace the groove more stably, resulting in clearly positive effects on sound quality — such as improved resolution of fine details, better clarity, and more defined low-end reproduction.

In this way, even if you have an extremely precise turntable and a high-performance cartridge, you cannot realize their full potential if record eccentricity causes large wow and flutter.

Eccentricity prevents playback frequency from reproducing at the correct frequency.

Eccentricity causes the cartridge to swing from side to side.

How Does the ES-001 Detect Eccentricity?

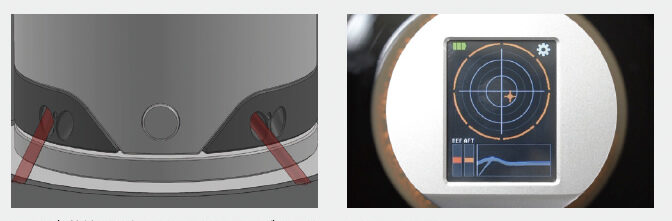

This eccentricity detection stabilizer uses two sets of infrared LEDs and PSDs (Position Sensitive Devices), placed at a 90-degree angle to each other. These sensors detect changes in the position of the end groove near the innermost radius of the record. If the record is perfectly centered, the position of the end groove—when viewed from the absolute center of rotation (the spindle center)—should remain constant. By using the two sensor readings, the system calculates the offset between the current center of rotation and the absolute center.

Interestingly, a similar approach was used in the past by Nakamichi’s eccentricity-correcting turntable system. That system used a mechanical “center search rod” to detect the position of the end groove. While the ES-001 takes a non-contact optical approach to detect the same groove, both methods rely on the end groove as a reference point.

The microcontroller calculates the offset between the current rotational center of the record and the absolute spindle center, and this offset is shown on the stabilizer’s display. Based on this display, the user manually nudges the record on the platter so that the record’s rotational center matches the absolute center, effectively reducing or eliminating eccentricity.

If a record has no gap between the spindle and the center hole, the position cannot be adjusted. However, by using the provided reamer to slightly enlarge the hole, adjustment becomes possible.

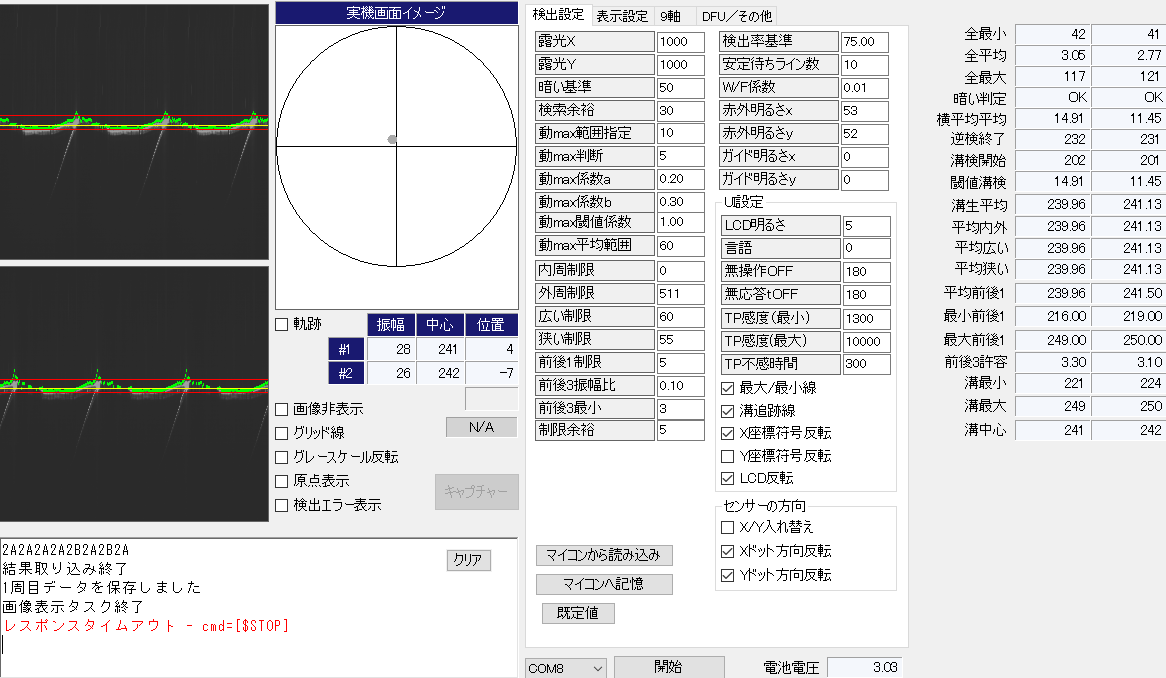

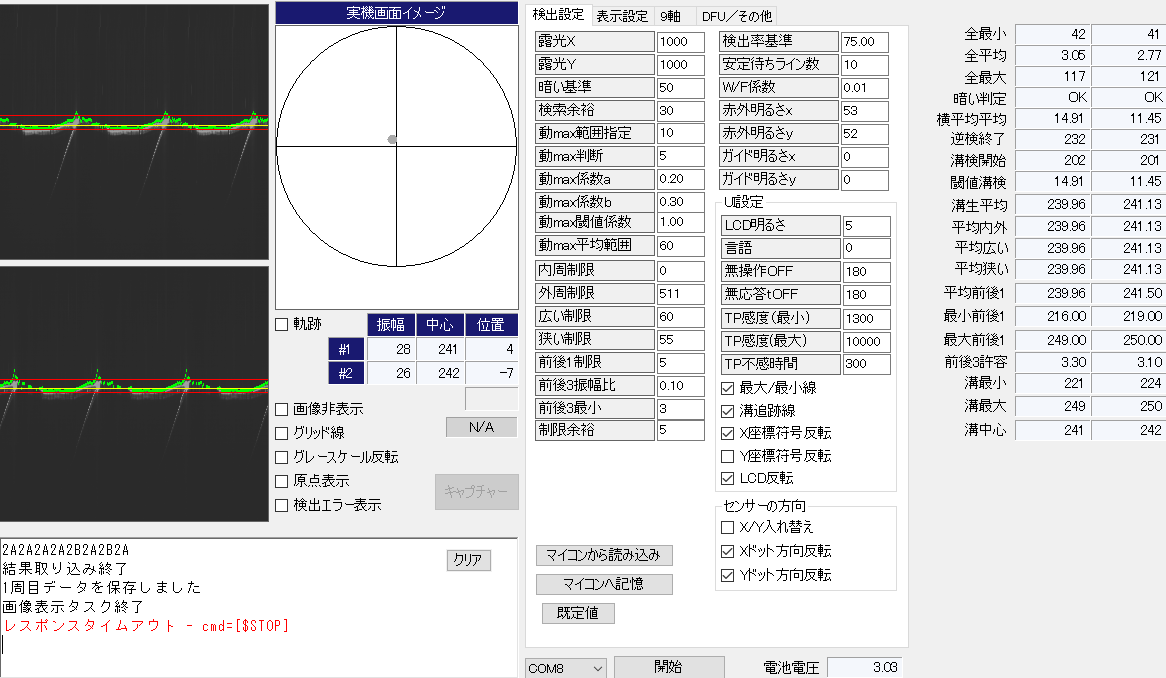

Right: Detection using two infrared sensors and a linear image sensor. Left: Eccentricity adjustment screen

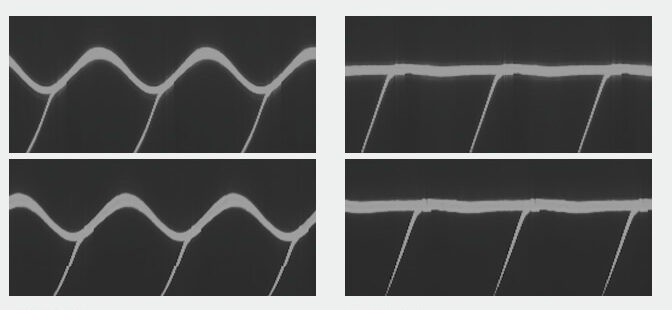

Example of linear image sensor output left: with eccentricity right: without eccentricity

Development History: How to Measure the End Groove?

Our discussions on whether we could develop a product to solve the problem of record eccentricity began around the fall of 2019.

To measure the eccentricity of a vinyl record, we first needed to find a part of the record that forms a true circle and observe its rotational behavior.

However, the music groove spirals inward, and due to manufacturing variations, the shape of the record itself cannot be reliably used.

The only part of a vinyl record that can be considered a true circle is the end groove, so the first challenge was:

How can we accurately detect the position of this end groove?

We initially considered a stabilizer-style approach, but at the time, we assumed that it wouldn’t work because the stabilizer rotates with the record, making it impossible to measure changes in position.

Eventually, thanks to an idea from one of our engineers—using a bearing to stabilize the detection part—we created a prototype that successfully allowed fixed-point detection while the stabilizer rotated with the record.

This breakthrough became the core invention behind the ES-001, and we filed a patent accordingly.

At first, we thought this would lead to productization within six months.

But what followed were many unexpected difficulties…

Unexpected Challenge: Out-of-Spec Records

As we proceeded with development, we discovered that many records did not conform to the standard end groove diameter. Out of 100 records tested, many lacked end grooves in the specified location. Some had oversized labels, autographs inside the groove, or music grooves cut nearly to the end groove.

Furthermore, some black records had low reflectivity, others had irregular reflectivity, and color records often transmitted too much light or saturated the sensor. Clearly, the end groove had never been intended for such precise detection.

With such variability, a design that worked only for in-spec records would fail for about half of all discs. A product that only works on 50% of records holds no value for customers.

Example of actual measurement of end groove position

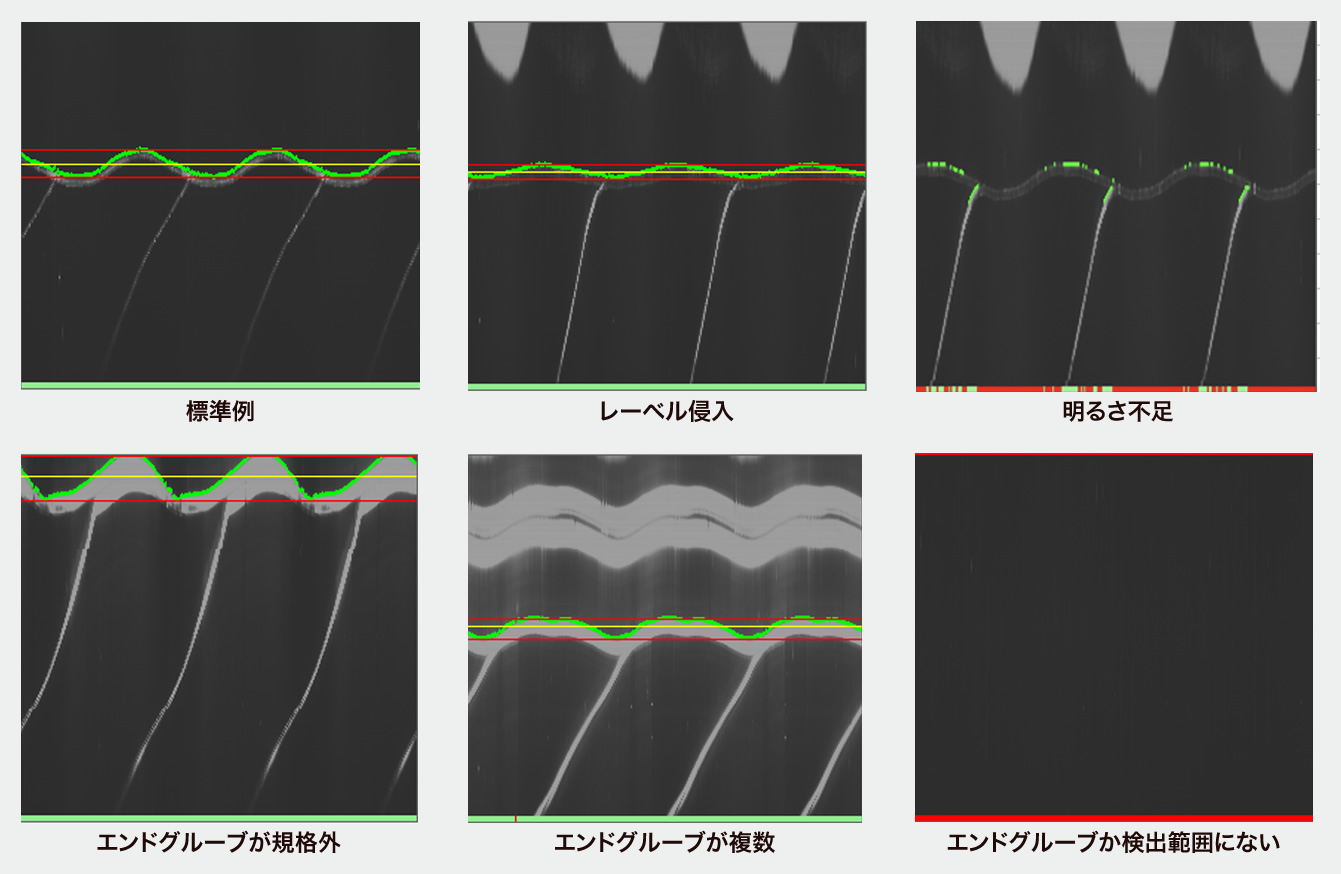

The ES-001 uses infrared LEDs to illuminate the end groove. The reflected light is measured by sensors, and brightness changes are processed by a microcontroller to detect groove positions. If there’s only one groove, detection is easy. But when labels or multiple grooves interfere, the software must distinguish the true end groove.

While humans can easily do this visually, it’s extremely difficult to code this logic. Variability in groove shape is effectively infinite. We had to create a simple yet robust algorithm that could distinguish grooves reliably under all conditions.

Our algorithm is our core know-how, so we won’t go into technical details. But for nearly two years, we refined our detection logic through repeated testing: algorithm design → measurement → troubleshooting → revision → re-testing. Like filtering water through finer and finer mesh, we gradually improved accuracy.

As a result, the final version could accurately detect the end groove in 95–98% of black vinyl records (per DS Audio testing). We decided to commercialize the product. The only major limitation that remains is with color vinyl, which cannot be reliably measured due to translucency or excessive reflectivity.

Create a virtual software on Excel and calculate the data obtained from the sensor to see if the shape of the end groove is properly recognized. If the end groove shape is not properly recognized, the measurement algorithm is reconsidered and the same process is continued.

Example of software under development. Virtual software created on Excel is transferred to the actual software to check its operation.

All for the Future of Analog

The development of this eccentricity detection stabilizer took two and a half years.Our chief engineer, Mr. Kasai, was fully dedicated to the project, and even the external software engineer worked almost exclusively on it.For a small company like ours, this was by no means a minor investment.

Even from the first year of development, a simple calculation made it clear that this project would likely result in a financial loss rather than a profit.The number of units we could expect to sell was limited, and the production cost—based on even the most minimal component estimates—was already known to be high.

And yet, we didn’t cancel the project.

Why?

Because we believed that solving the problem of record eccentricity—a major remaining flaw in analog playback—was essential to shaping the future of analog.

Our brand concept at DS Audio is:“Creating the future of analog music.”

We believe this guiding principle must never be sacrificed for short-term numbers like sales or profit.It should always come first in our decision-making as a company.

We felt that if we could bring this stabilizer to life,it would become a product that truly contributes to the future of analog—something that could give back, even just a little, to the culture and history of analog music.That’s why we pressed on with development, even if it meant disregarding profitability.

As a result, the development took far longer than expected.But in 2022, we were finally able to release a stabilizer that solves the serious issue of record eccentricity, which greatly affects playback.

Since then, many users have shared their feedback, saying things like:

“I had no idea eccentricity had such an impact,”

“I can’t listen to records anymore without this stabilizer.”

Several years have passed since we released the ES-001.To allow more people to enjoy eccentricity-free record playback,we have now released a more affordable model: the ES-002 Reference/Core.

If this stabilizer can help even a little in shaping the future of analog playback, we would consider that our greatest reward.

— Aki DS Audio